Scale models of buildings and structures in Russia

Production company JSC "Kursportalen" specializiruetsya in the production of various steel structures. One of the areas is the manufacture of industrial greenhouses of contemporary designs in which you can grow and harvest year round with minimal costs.

To attract attention to its high-quality products, the company often takes part in exhibitions.

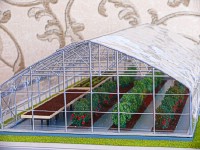

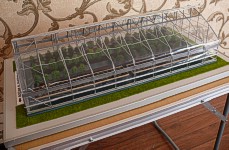

To demonstrate the beneficial differences plastic greenhouses of JSC "Kursportalen" placed an order for the production of the layout of the industrial greenhouse.

The layout of the greenhouse

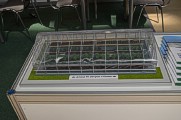

The layout is realistic.

Scale 1:35.

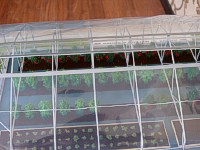

On the layout shown the plants (tomatoes and cucumbers), as well as seedlings, which are grown on special tables. These tables are manufactured in the company - customer layout.

At the top of the layout opens the window to ventilate the greenhouse in the summer.

On the sides of vents of the film is also shown below in the demonstration, the visitors could better get an idea of the advantages of the technological solutions to the greenhouse.

On the perimeter of the greenhouse covered with transparent polycarbonate. The layout of the greenhouse demonstrates that the materials are transparent, that enables sunlight is the best way to affect a quick ripening and seedling growth.

The scale model applied is durable and high quality materials.

The frame of the greenhouse is made of metal.

Greenery is made of highly realistic imitation of imported materials (Germany).

Applied PVC, plexiglass, chipboard, film.

|  |  |  |  |  |  |

|---|

|  |  |  |  |  |  |

|---|

|  |  |  |  |  |  |

|---|

|  |  |  |  |  |  |

|---|

Models of greenhouses, layouts of hangars and various buildings made from metal and can be ordered in the layout of the Studio Models Russia.

The modern development of the means of production creates the false impression that the manufacture mastabah models is something of a game.

In the Internet you can find a huge number of fake business plans, wonderful stories and other fictions about the ease of use of the equipment. And allegedly with the help of this equipment as if by magic one button born scale models of buildings and structures.

In fact, the production of scale models is a complex design and technological process in which the participation of specialists of different professions.

False information about the ease of achieving success with the help of certain equipment fetus manufacturers of this equipment.

And it is because of this false representation goes by the wayside, most importantly the complexity of the production of scale models.

One person can do the work of 8 to 12 man hours in one day.

Underlying the complexity scale model is in the General case 2000 labor times. Thus to perform a scale model in a month you need to learn from 8-12, and 80-100 hours a day. Ie 10 times more.

Manufacturers grief business plans do not take into account that every person engaged in the modern production of scale models is already running more than two or three colleagues.

This is due to the high competence in the use of automation.

Virtuosity with a computer, printers, cutting plotters, machine tools, 3d printers, the modern technology of machining and 3d modeling are the components, which are indispensable for the effective application of expert on the team producing the architectural scale model.

Otherwise, the following occurs.

People are deceived information. Namely:

1. Banks advertise loans... - take out a loan. Other people's money, spent easily.

2. The Internet screams - we will create a website and promote it to the top... - man website orders and pays for SEO. Not knowing the Ford spent so much money that simply can not be earned if the customer will come immediately.

3. The Internet screams - order equipment... we have a person buys equipment for the production of scale models. But to produce a scale model should be able to use this equipment, this equipment shall be suitable, effective, require little time for repairs and maintenance, to have cheap consumables and finally to do exactly what will be needed. But usually the first thing you cannot do is to load the equipment. Who's going to do 3d models for this equipment? The production model is the same man-hours. Either by yourself or need to hire an expensive and often capricious specialist.

Another fact - book on the side to make 3d models can also be work. It is necessary to define a problem, to give the drawings to negotiate the price to pay for the work, to take the job... All this man-hours.

4. The customer turned... - you need to calculate the labor costs for manufacturing specific unique products. It too work. The complexity of exact calculation of the cost of the layout from a professional economist, secured the necessary tools - is not one hour. And for what money to feed such a specialist? Next is to enter into a contract, an invoice, accept payment, order and pay for the materials.

5.6.7.8. etc.

This list is long.

However, the conclusion from this is obvious. To order any scale model must take into account that on the market there are too many people who are unable to perform this time-consuming job. And before turning to those who promise to produce an architectural model for a penny, it is better to err and to call in a professional Studio, with a solid portfolio with photos of scale models do not pull off from other sites, and is marked with its own watermarks.

Despite the seeming ease of manufacture scale models is a really complex design and engineering challenge, in which one of the main roles is the economic component.

It is an integrated approach to the activities of the enterprise, the creation of a creative team, able to act quickly and smoothly to fulfill orders accurately and on time, to the model workshop MaketyRossii.RF main focus.

3D printer by itself cannot provide advantages in the production of scale models . Without a strong team of skilled hands and heads is just a toy for printing unnecessary 3d meshes from the Internet.

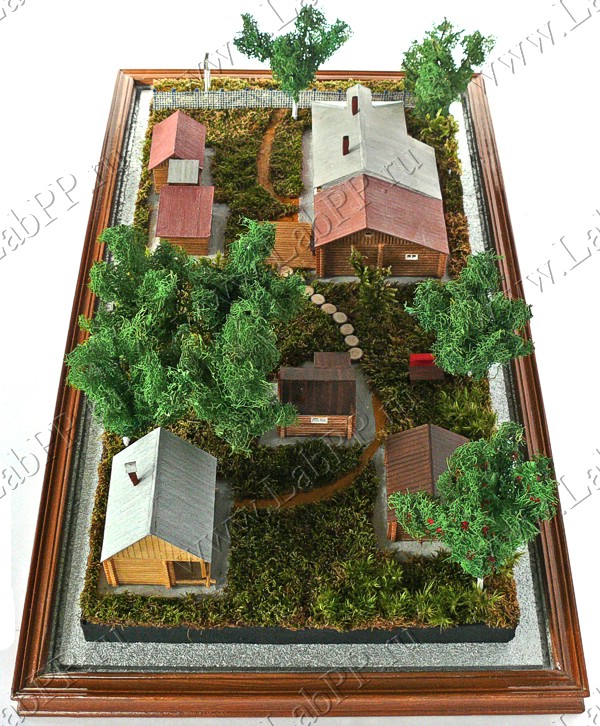

Laboratory design of space offers a new kind of exclusive gifts:

making an exact copy of terrain area, structures

Manufacturer replica location, site, structures.

From the photographs, plans, sketches, memoirs.

Lights. Relief.

Before starting the work carried out a computer model, its images agreed with the customer.

In the course of execution of works sent to the photo report.

The dome of transparent plastic.

Batteries are inserted from below.

Any size.

Installation of moving parts, the railroad with a moving composition on which you installed a video camera.

The main difficulty making the layout is to convey the image of the most realistic.

Architectural and prototyping workshops to build the layout of the modern apartment house using cardboard and paper.

At the same time making models of complex architectural structures with stucco to them is unacceptable to labor or inaccessible due to technological reasons.

Many people try to use equipment that is designed for rapid prototyping machine parts ..

Such as three-dimensional model of the existing three-dimensional printers can produce such a layout as a whole. However, the main shortcoming of the model performed on the 3D printer are:

- visible to the eye surface roughness;

- poor quality of detail;

- unreliability of staining and discoloration, even in normal lighting;

- high unit cost ($ 0.2 per cubic centimeter for the layout shown in pictures that would mean the cost of 1.8 million rubles).

Unlike them, our company has all the features from the construction of three-dimensional model of the building prior to its manufacture. It uses a specially developed methodology for creating realistic strategies for making each object.

This methodology allows you to maneuver the technological processes of production so as to rapidly integrate the manual labor and high-precision automated equipment.

This so-called integrated production technology, the integration of CAD and ACSPSW (CAD / CAM system integration).

This approach allows not only qualitative but also in real time and real money to carry out sophisticated products.

Because of the complexity and heterogeneity of the process, the planning in the usual model workshop usually not conducted at all, and the time assigned to a large extent "from the ceiling."

Unlike them, our laboratory uses the method of integrated planning based on Gantt charts, structural and functional analysis. That provides a unique opportunity to take advantage of the methods of production and creative planning at a time.

That is why in such a difficult time, we do not have turnover. We have enough orders and have the opportunity to perform them for you at the highest level in a short time and at reasonable prices.

A mock-up, performed by our experts differ in that they possess:

- moderate cost;

- reasonable and accurate dates of manufacture;

- stability over time;

- highly realistic.

We - vykokotehnologichnaya company with good laboratory facilities and its own work the software and make sure that our customers do not spend extra money.

Therefore, the cost of the architectural layout - from 5,000 rubles, depending on complexity.

Time frame layout - from 2 days.

Even the photographs or verbal description can be built for you layout. Because first, we construct three-dimensional computer model and sends it in the form of images from different angles to you for approval.

Possible to produce LED backlight, simulations of water and natural phenomena, the installation of cameras at the sites layout (eg on a moving locomotive).

Materials - high quality cast plastic, wood, polystyrene, glass, natural materials are specially stabilized wildlife on German technologies and materials - simulators.

Used in the manufacture of precision equipment and software to create a realistic and complete the appropriate size.

Please apply to the manager of the clusters modeling . It will be the terms of reference, a standard contract and send you for approval.

You can pick it yourself, or we'll send you his transport company.

Work begins when you receive a 40% prepayment. The rest - after the approval of your results and the signing of the Acceptance of work performed.

During the work, we will send you a photo reports on which you can have an idea of future results and timely adjustments to the details.

Each customer receives a gift is one of the excellent jewelry an established jointly with the Italian specialists, our own production (Glass Art Intuition).

More Articles...